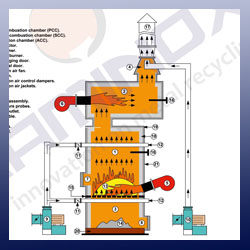

We Bioline Technologies are Manufacturers, Suppliers, Provider, Fabricators, Exporters Industrial Waste Incinerator . An Industrial Waste Incinerator is a specialized piece of equipment designed to safely and efficiently dispose of various types of industrial waste by combusting them at high temperatures. These incinerators are used by industries to manage hazardous and non-hazardous waste materials, reduce waste volume, and comply with environmental regulations. Here is an overview of industrial waste incinerators and their operation. The incinerator consists of a primary combustion chamber where industrial waste is loaded for incineration. This chamber is typically lined with refractory materials to withstand high temperatures.Many industrial waste incinerators have a secondary combustion chamber downstream of the primary chamber. This chamber provides additional residence time for combustion gases at high temperatures, ensuring complete destruction of harmful pollutants and volatile organic compounds (VOCs).Combustion burners or heating elements provide the necessary heat to maintain high temperatures within the chambers. Proper temperature control is essential for efficient waste incineration.Air supply systems provide oxygen for combustion and help maintain the required temperature levels within the chambers. Adequate oxygen supply is crucial for complete combustion of waste materials.Modern industrial waste incinerators are equipped with advanced control systems that monitor and regulate temperature, airflow, and combustion parameters.

These systems help optimize performance, safety, and emissions control.To minimize air pollution and emissions of harmful gases, industrial waste incinerators are equipped with pollution control devices such as scrubbers, baghouses, and filters. These systems capture and neutralize pollutants before they are released into the atmosphere.Various types of industrial waste, including hazardous and non-hazardous materials, are loaded into the primary combustion chamber of the incinerator. These wastes can include chemicals, solvents, oils, plastics, and more.The incinerator's burners or heating elements are activated, raising the temperature inside the primary combustion chamber to levels sufficient for complete combustion of waste materials. High temperatures (typically above 1000°C or 1832°F) ensure the destruction of hazardous substances and reduction of waste volume.In cases where a secondary combustion chamber is present, combustion gases are directed into this chamber for further processing at elevated temperatures, enhancing the destruction of pollutants and VOCs.Emission control devices like scrubbers, filters, and baghouses capture and treat the combustion gases, removing harmful substances and particulate matter. This helps meet stringent emission standards.After incineration, the remaining ash and non-combustible residues are collected and properly disposed of according to regulations.Efficient and complete destruction of hazardous waste materials.Reduction in waste volume.Prevention of the spread of hazardous substances.Compliance with environmental regulations.Safe disposal of difficult-to-manage waste streams.Industrial waste incinerators are crucial tools for industries that generate hazardous waste materials. Proper operation and maintenance, along with adherence to regulatory guidelines, are essential for their safe and effective use while minimizing environmental impact. We Bioline Technologies are deeply engaged in offering a wide array of Industrial Waste Incinerator to our valuable Clients located in Mumbai, in Navi Mumbai, in Thane and all over India.