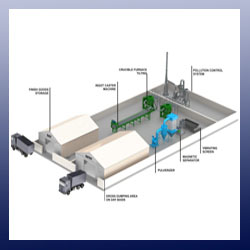

We Bioline Technologies are Manufacturers, Suppliers, Provider, Fabricators, Exporters Aluminium Dross Reprocess Plant.An Aluminium Dross Reprocess Plant is an industrial facility designed to recycle and recover valuable materials from aluminum dross. Dross is a waste byproduct generated during the aluminum smelting or casting process. It consists of impurities, oxides, and non-metallic materials that accumulate on the surface of molten aluminum. Reprocessing dross is essential for minimizing waste, conserving resources, and reducing environmental impact. Here's some information about an Aluminium Dross Reprocess Plant:The first step involves collecting aluminum dross from various sources, such as aluminum smelters, die-casting plants, or secondary aluminum processing facilities. Dross can be in the form of skimmings, slag, or aluminum-rich residues.To prevent any remaining molten aluminum from solidifying and to enhance the efficiency of subsequent processing, the collected dross is often cooled using methods like water quenching or air cooling.The cooled dross is then subjected to a separation process. This typically involves mechanical processes or technologies like vibratory screens, magnetic separators, and eddy current separators to separate aluminum from non-metallic materials and contaminants.The separated aluminum is recovered and processed further. Depending on the plant's capabilities, this may include remelting the recovered aluminum to produce aluminum ingots or billets for reuse in manufacturing.The non-metallic residues and impurities separated from the dross are typically treated separately.

Some of these materials may be recycled or disposed of in an environmentally responsible manner.Throughout the process, quality control measures are implemented to ensure that the recovered aluminum meets specific standards and customer requirements. Aluminium Dross Reprocess Plants aim to recover as much aluminum as possible from dross to minimize waste and maximize resource utilization.These plants must adhere to environmental regulations to control emissions and minimize environmental impact, especially when handling hazardous materials that may be present in dross. Safety measures are critical due to the potential for high-temperature processes and the handling of potentially hazardous materials.Strict quality control is essential to ensure the recovered aluminum is of suitable quality for reuse in various industries.Some dross reprocessing plants incorporate energy-efficient technologies and waste heat recovery systems to optimize energy use.The production volume and type of recovered aluminum may be influenced by market demand and specific industry needs. We Bioline Technologies are deeply engaged in offering a wide array of Aluminium Dross Reprocess Plant to our valuable Clients located in Mumbai, in Navi Mumbai, in Thane and all over India.